Company Profile

Shenzhen Yaoqun Industrial Co., Ltd. is a large-scale shoe-making enterprise established in 1993, integrating R&D, design and production of high-end women's shoes. Yaoqun has 7 branch offices and nearly 10,000 employees. Its business covers the production of accessories from footwear production to outsole, heel, buckle and fitting.

In 2017, Yaoqun and Kings 3D reached a strategic cooperation on 3D printing of shoe molds and purchased several SLA 3D printers Kings6035 and Kings7255. During the partnership, Kings 3D provided a complete set of 3D printing solutions for footwear to help improve efficiency and reduce costs.

Kings sla 3d printer

Challenge

As a shoe-making enterprise, Yaoqun has cooperated with well-known brands such as Daphne, Thousand Baidu, Mi Si Luo Ni, Yi Er Kang, Kang Li, Fu Gui Bird and Bai Tian Sen. Thousands of new models are created each year, which is a big challenge for the design and development department. In the past, it relied on people's tactics to deal with this problem.

Solution

Yaoqun is one of the earliest companies in the shoe industry to use 3D printing technology to improve development and production efficiency. This is clearly why the company has won the favor of customers.

1. By using 3D printing technology, it takes about a week to get the sample, and now it can be printed in 1-2 days. With the same number of people, the number of new models developed each month has increased by 2 times.

2. In the design section, Kings 3D is equipped with RhinoOrang software for Yao Group to assist 3D personnel in rapid modeling and repair, and the overall efficiency has increased by about 40%;

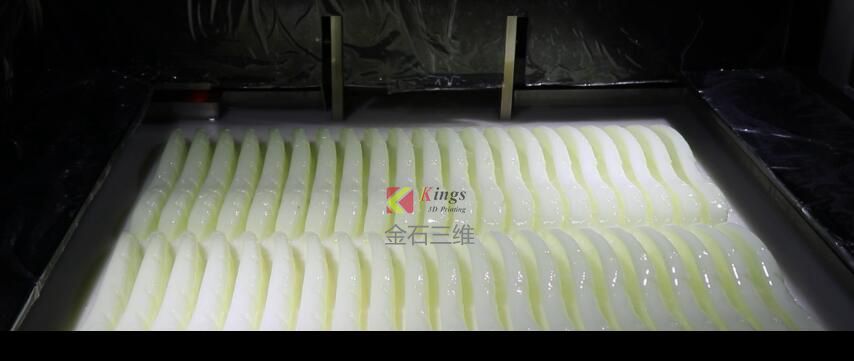

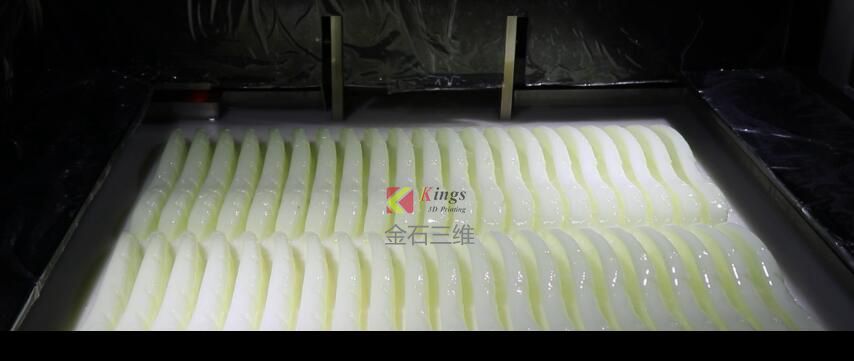

3. On the application side, Yaoqun prints the designed product model according to the actual situation. There are a hard material for shoe models and molds and a soft material for try-on models. After confirming the sample, Kings SLA 3D printer can quickly print the shoe mold for sand casting. If there is a small batch of urgent orders, the mold can also be printed directly.

Aiming at the vacuum pressure resistance, abrasion resistance, high temperature resistance and rapid cooling of the mold in the application, Kings 3D provides special technologies such as shoe skeleton design and polymer material composition modification to less material use. By printing the model and molds, it helps shoe manufacturers achieve the highest productivity at the lowest cost.

Technical case

For example: a pair of shoe casting molds, in order to ensure pressure resistance, many will make the thickness 2mm or even 3mm. Kings 3D printers can be set the structure on the surface and fill it with replacement materials to control the wall thickness to 1.5mm or less. This actually saves half of the material and doubles the printing efficiency.

With Kings SLA 3D printing technology, Yaoqun Industrial has achieved 24 hours unmanned and eco-friendly manufacturing. Once again it opens the gap with other peers, and will surely win a broad market expectation.

You might want to know more:

· Resins for Shoe Model and Mold

· What materials should we choose for 3D printing shoes?

· How Does Kartel Kalip Grow into a Leading Shoe Mold Maker in Turkey?

·Shoe Industry: Should I Choose Desktop DLP 3d Printer or Industrial SLA 3D printer?