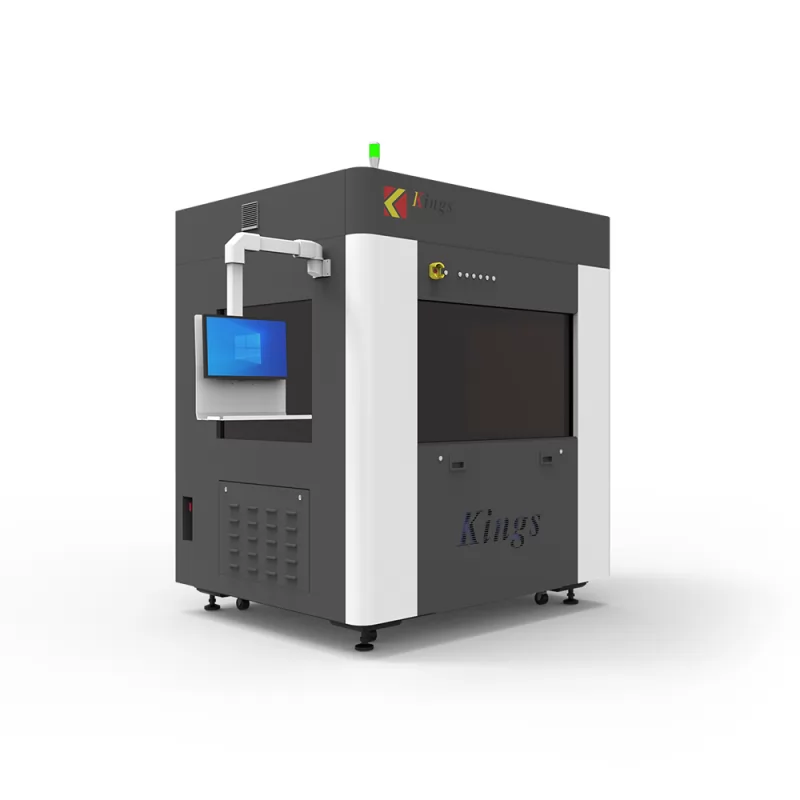

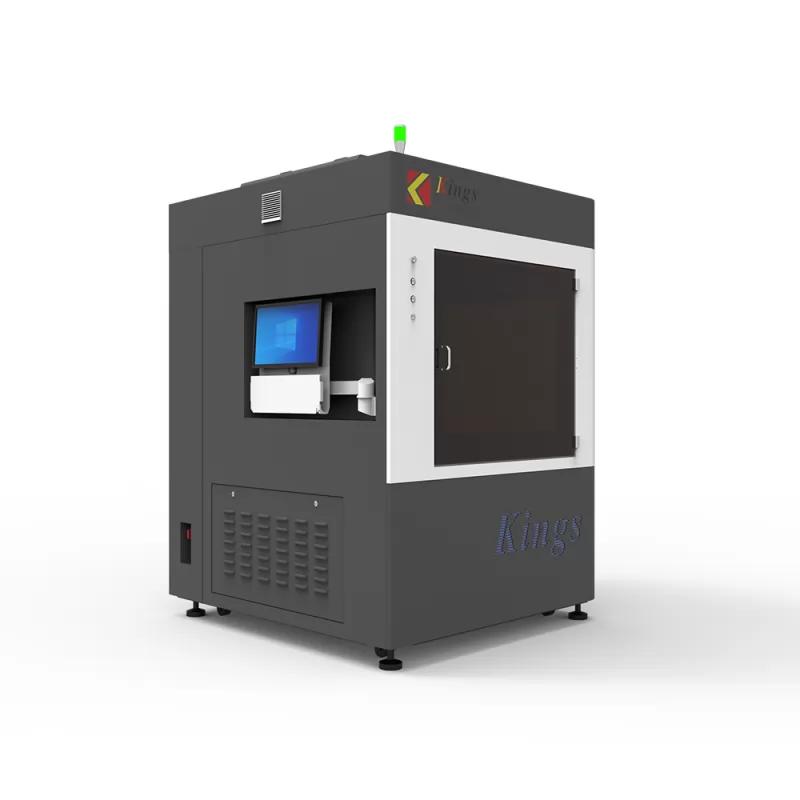

Description

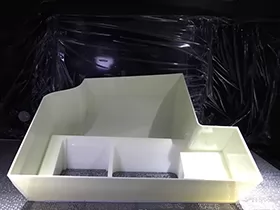

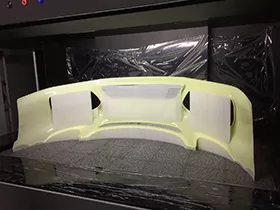

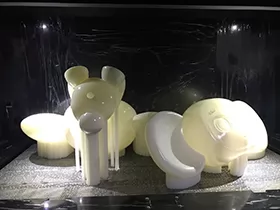

We've provided 3D printing services for single products or short run manufacturing in consumer goods, engineering parts, architectural models, medical devices, jewelry design, automotive technology, and more. We stay focused on cutting edge technology and strict operational standards while maintaining the lowest prices in the industry for plastic and metal online 3D printing services. Contact us to get your 3D Printing Pro!

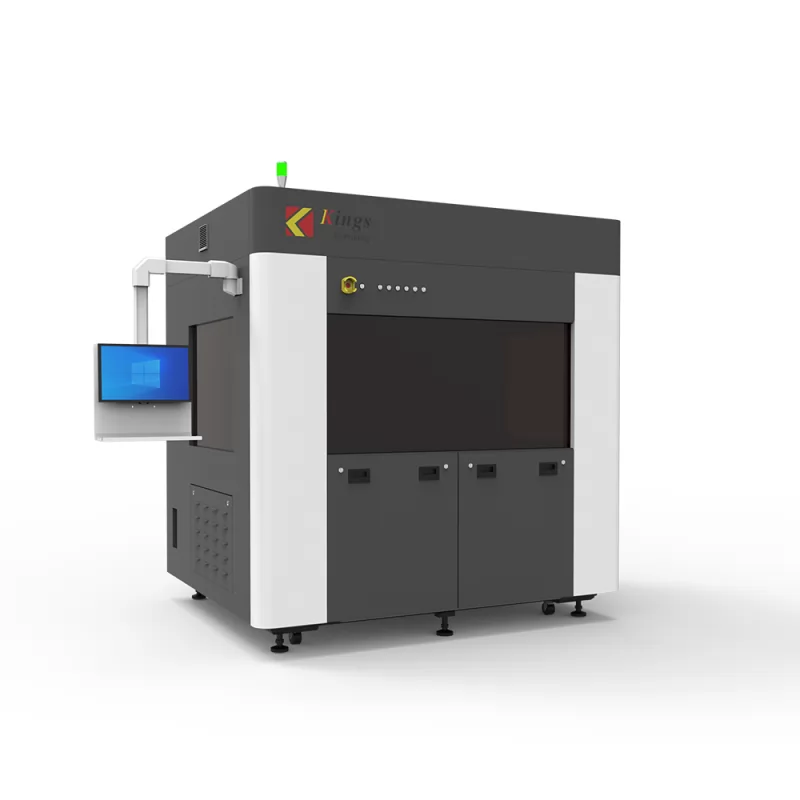

Product Parameters of 3D printing Pro

| 1.BASIC INFORMATION |

| Max Printing Size | 1700*800*600mm |

| Machine Size | 247cm(W)*168cm(D)*230cm(H) |

| Rated Power Consumption | 2.2KVA |

| Machine Weight | 3600kg |

| 2.LASER SYSTEM |

|

| Laser Type | Solid-state frequency tripled Nd: YV04 |

| Wavelength | 355nm |

| Power | Resin Surface Power≥ 300 mW |

| 3.OPTICAL & SCANNING SYSTEM |

| Scanning Mode | Germanic galvanometer scanner |

| Variable Beam System | Galvo/Closed-loop |

| Beam Size (diameter @1/e2) | 0.085-0.8mm (Variable Beam) |

| Max Scanning Speed | 18.0m/s |

| 4.RECOATING SYSTEM |

| Main Sturcture | Marble recoater frame, marble elevator holder and marble scanning system base |

| Coating Mode | Intelligent position vacuum recoating |

| Vertical Resolution Ratio | 0.0005mm |

| Repeat Positioning Accuracy | ±0.01mm |

| Layer Thickness | 0.05mm~0.25mm |

| Accuracy | L≤150mm, ±0.1mm;

L>150mm, ±0.1%*L |

5.CONTROL SOFTWARE

|

| Motion Control System | Closed-loop |

| Machine Control Software | KINGS 3D control software |

| Input Data File Format | STL/SLC |

| Operating System | Windows 7/10 |

| Network Type and Protocol | Ethernet,TCP/IP |

| 6.INSTALLATION CONDITION |

| Electrical Requirement | 200-240VAC 50/60Hz, single-phase,10A |

| Ambient Temperature | 20-26ºC (72-79℉) |

| Relative Humidity | <40%,non-condensing |

| First Tank Resin | 1300kg |

| 7.WARRANTY |

| Machine | Two years |

| Laser | Two years |

Advantages of 3D Printing

This production process offers a range of advantages compared to traditional manufacturing methods. These advantages include those related to design, time and cost, amongst others.

1. Flexible Design

3D printing allows for the design and print of more complex designs than traditional manufacturing processes. More traditional processes have design restrictions which no longer apply with the use of 3D printing.

2. Rapid Prototyping

3D printing can manufacture parts within hours, which speeds up the prototyping process. This allows for each stage to complete faster. When compared to machining prototypes, 3D printing is inexpensive and quicker at creating parts as the part can be finished in hours, allowing for each design modification to be completed at a much more efficient rate.

3. Print on Demand

Print on demand is another advantage as it doesn’t need a lot of space to stock inventory, unlike traditional manufacturing processes. This saves space and costs as there is no need to print in bulk unless required.The 3D design files are all stored in a virtual library as they are printed using a 3D model as either a CAD or STL file, this means they can be located and printed when needed. Edits to designs can be made at very low costs by editing individual files without wastage of out of date inventory and investing in tools.

4. Fast Design and Production

Depending on a part’s design and complexity, 3D printing can print objects within hours, which is much faster than moulded or machined parts. It is not only the manufacture of the part that can offer time savings through 3D printing but also the design process can be very quick by creating STL or CAD files ready to be printed.

5. Cost Effective

As a single step manufacturing process, 3D printing saves time and therefore costs associated with using different machines for manufacture. 3D printers can also be set up and left to get on with the job, meaning that there is no need for operators to be present the entire time. As mentioned above, this manufacturing process can also reduce costs on materials as it only uses the amount of material required for the part itself, with little or no wastage. While 3D printing equipment can be expensive to buy, you can even avoid this cost by outsourcing your project to a 3D printing service company.

6. Ease of Access

3D printers are becoming more and more accessible with more local service providers offering outsourcing services for manufacturing work. This saves time and doesn’t require expensive transport costs compared to more traditional manufacturing processes produced abroad in countries such as China.

7. Environmentally Friendly

As this technology reduces the amount of material wastage used this process is inherently environmentally friendly. However, the environmental benefits are extended when you consider factors such as improved fuel efficiency from using lightweight 3D printed parts.

8. Advanced Healthcare

3D printing is being used in the medical sector to help save lives by printing organs for the human body such as livers, kidneys and hearts. Further advances and uses are being developed in the healthcare sector providing some of the biggest advances from using the technology.

Get Further Advice On 3D Printing

Need help with determining whether 3D printing is the right process for you?

Contact our team of world-leading experts with over 14 years of experience in the additive manufacturing field.

Our technology experts help to ensure our customers apply the correct technology process depending on each individual or company requirements.