Explore a world of customized automotive solutions through

our cutting-edge 3D printers.

Your journey to unparalleled vehicle

customization starts here.

OUR CAR

CUSTOMIZATION

Explore a world of customized automotive solutions through

our cutting-edge 3D printers.

Your journey to unparalleled vehicle

customization starts here.

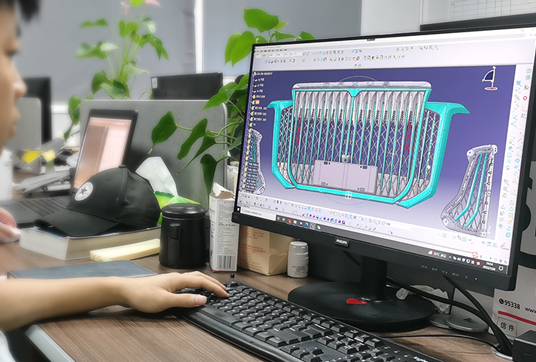

3D PRINTING IN

CAR MANUFACTURING

Creatively revolutionizing 3D printing in the automotive industry, Kings proudly presents Kings ChongQing—a dynamic subsidiary.

Specializing in prototype manufacturing, vehicle customization, and cutting-edge modifications, we lead the charge for passionate automotive industry. Embrace innovation with Kings ChongQing and redefine your automotive journey!

Prototype manufacturing

Vehicle customization

Cutting-edge modifications

WHAT OUR

MACHINES DO

Printing of Interior and Exterior Prototype Components

Printing of Interior and Exterior Prototype Components

Printing of Lightweight Components

Printing of Lightweight Components

Small Batch Prototyping

Small Batch Prototyping

Prototype

Vehicle

Cutting-edge

Cutting-edge

APPLICATION

INTRODUCTION

Large Size:

Dimensions of 2000*550*700mm, traditional manufacturing methods (CNC) require splitting into numerous smaller pieces for production.

Complex Structure:

Traditional CNC machining involves mold creation, resulting in high production costs, design limitations, and substantial manual labor.

Low Precision:

Dependent on the operator's personal experience.

Long Design and Development Cycle:

Traditional CNC machining methods take 2 months.

Require splitting

Excessive cost

Long time

Low accuracy

The entire production process:

Design validation cycle reduced to just 1 week, an 80% time reduction.

Dimensional accuracy error < 1mm for the 2000mm size. A 67% reduction in manual labor costs, leading to a decrease in the final component's overall cost