Description

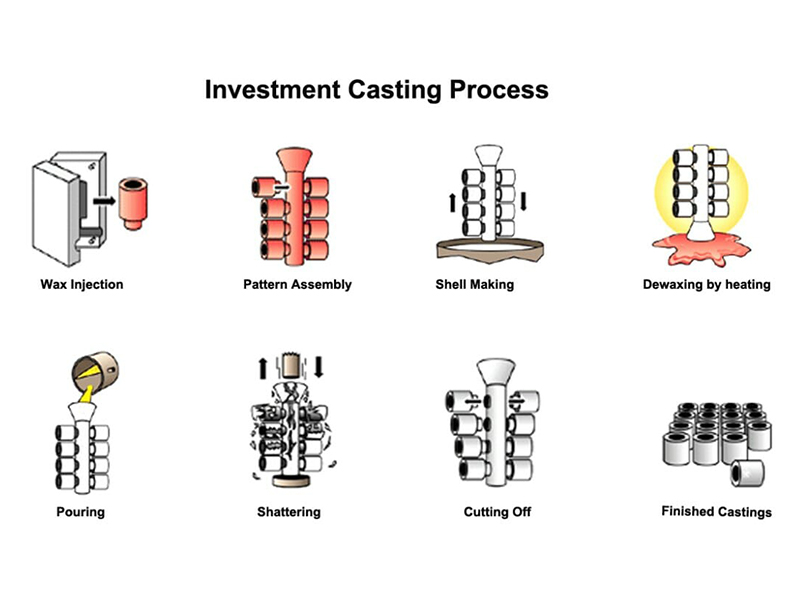

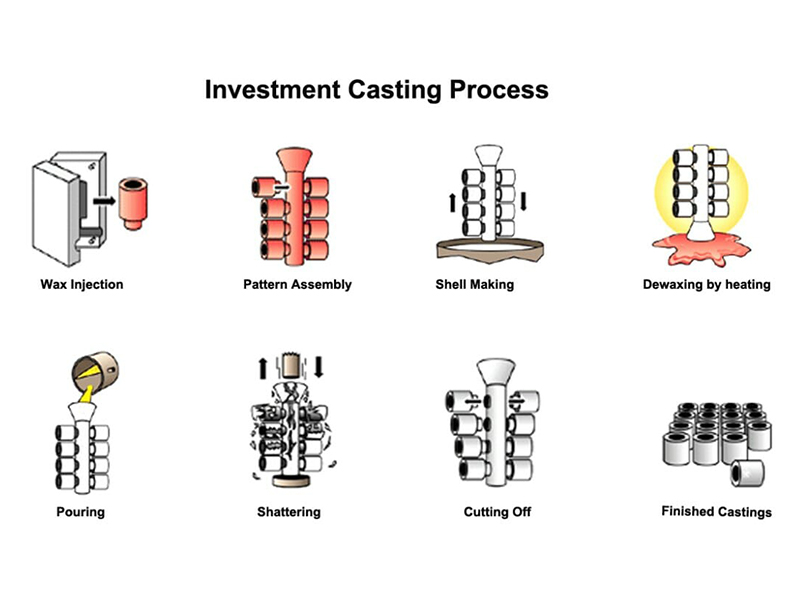

Investment casting (also called lost wax casting) is a manufacturing process which has been used for hundreds of years to create near-identical metal parts. The traditional investment casting is a successful process and has some degree of automation in the foundry industry, however, the high cost and time involved in the creation of tooling have limited the casting industry.

The SLA (Stereolithography) 3D printing technology offers a tool-less production of casting models solution, reducing the costs of creating model by 90%, and capable of producing casting models in one-tenth of the time(we call it quick casting). And it has been an ideal method for investment casting.

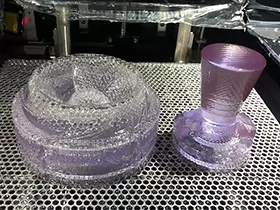

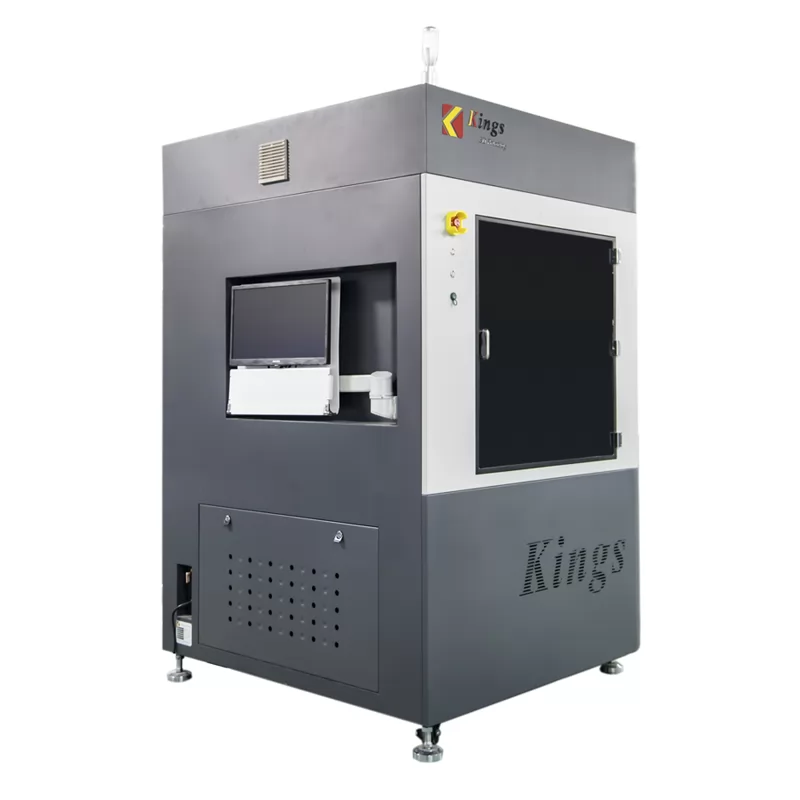

Kings 600Pro SLA 3D printer offers rapid production of quick casting models, which is capable of producing a high-quality aesthetic finish with tight tolerances. And with KS168C castable resin -that are fully industry-tested, the casting models can be completed in days. The 3D printed casting models are with an internal hexagonal support structure which adds strength to the models, allows for easy drainage, facilitates collapse of the pattern during thermal expansion to help avoid shell cracking, and helps to reduce part volume, weight, and material needed to create a solid part.

Advantages of quick casting models

· Turn-around time

Quick casting models can be printed by Kings 600Pro in as fast as one or two days, saving a lot of time.

· Tolerances

Quick casting models can achieve tolerances +/- 0.1mm; this is not possible with the tooling utilized in traditional investment casting

· Finish and detail

Quick casting models typically have a cosmetically superior finish to traditional casted parts, and allow for additional detail and geometries that are simply not possible with traditional investment casting

· Tooling

Quick casting models offer a tool-free, fast, reliable and accurate alternative to models created using tooling, reducing the costs of creating patterns significantly

Recommended 3D Printing Material: UV Resin KS168C