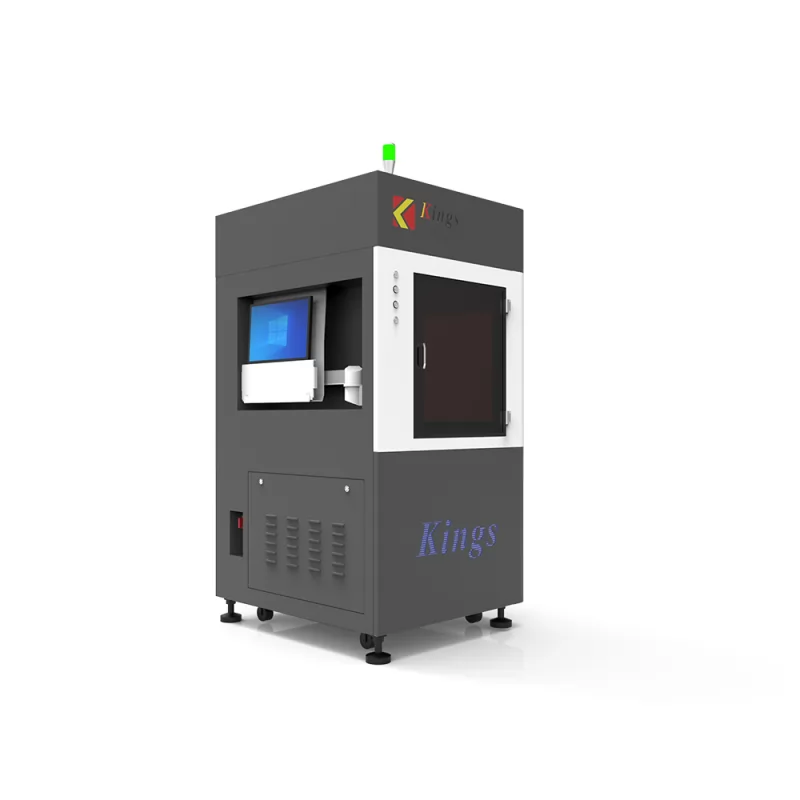

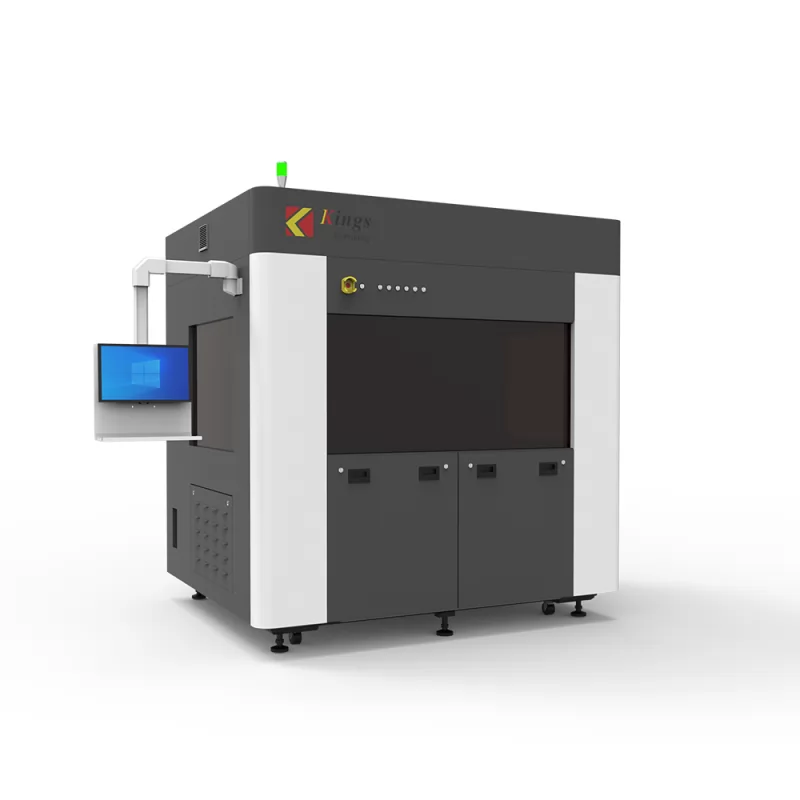

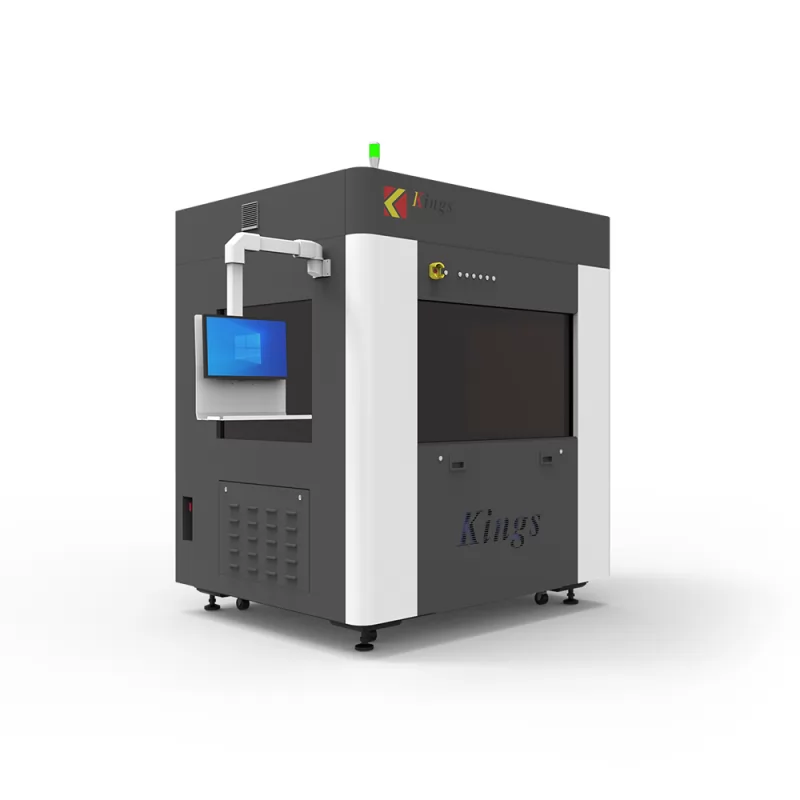

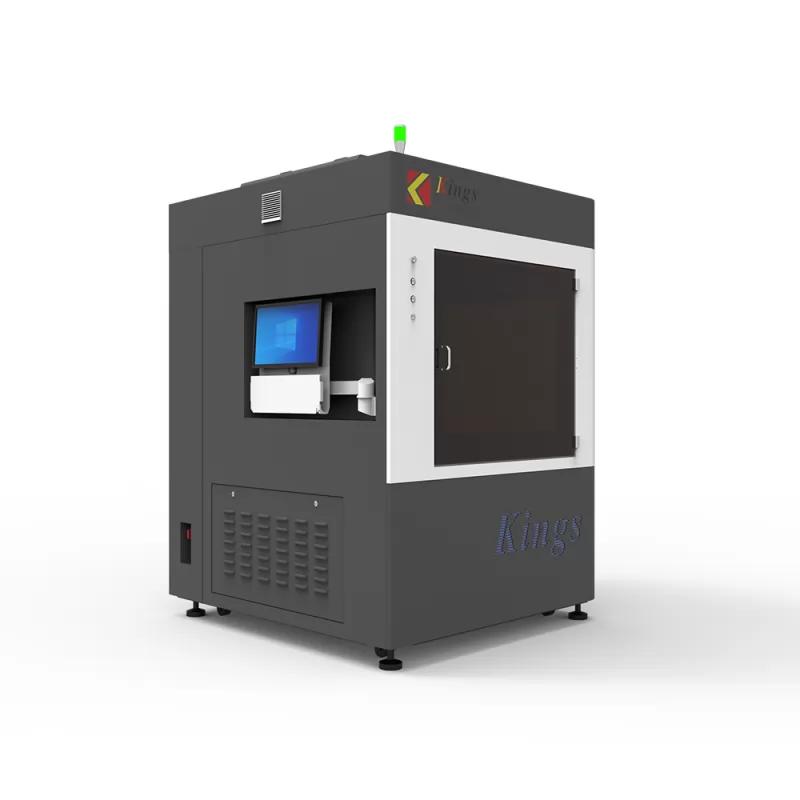

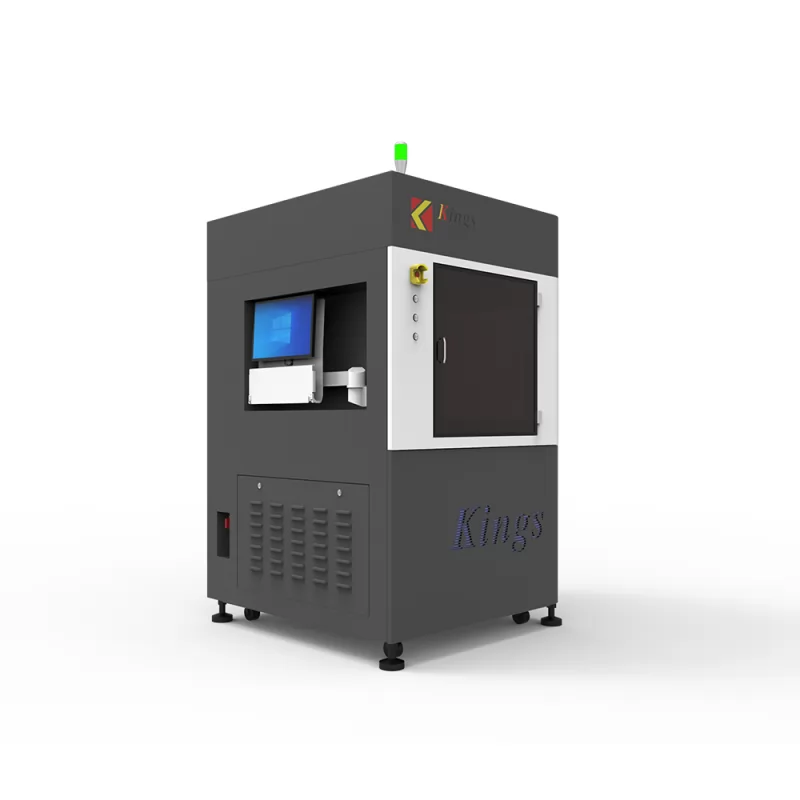

Stereolithography (SLA) is an industrial 3D printing process used to create concept models, cosmetic prototypes, and complex parts with intricate geometries in as fast as 1 day. A wide selection of materials, extremely high feature resolutions, and quality surface finishes are possible with SLA. Looking for the Best SLA 3D Printer? Welcome to contact us.

SLA 3D printing is primarily used for:

1.Parts requiring high accuracy and features as small as 0.002 in.

2.Good surface quality for cosmetic prototypes

3.Form and fit testing

Advantages of SLA 3D Printer

1.Stereolithography offers a lot of advantages, it can help you rapidly prototype, or develop your whole final product.

2.These photopolymer parts do not have the strength of Selective Laser Sintering (SLS) or FDM 3D printed parts, but can typically achieve much higher levels of detail and great complex geometries. As the photopolymer is UV sensitive, these products are susceptible to deforming and changing colors in sunlight. SLA is commonly used to generate highly detailed artwork, non-functional prototypes, and can be used to make molds in investment casting applications.

3.SLA parts have a really smooth surface finish, which is particularly adapted if you need a realistic prototype with high quality and detailed features, quite similar to injection molding parts. But resin parts printed with Stereolithography are not suitable for functional prototypes.

Specification of SLA 3D Printer

| BASIC INFORMATION |

|

| Max Printing Size | 450*450*350mm |

| Machine Size | 104cm(W)*117cm(D)*192cm(H) |

| Rated Power Consumption | 1.2KVA |

| Machine Weight | 720kg |

| LASER SYSTEM |

|

| Laser Type | Solid-state frequency tripled Nd: YV04 |

| Wavelength | 355nm |

| Power | Resin Surface Power≥ 300 mW |

| OPTICAL & SCANNING SYSTEM |

| Variable Beam System | Galvo/Closed-loop |

| Beam Size (diameter @1/e2) | 0.08-0.8mm(Variable Beam) |

| Max Scanning Speed | 15.0m/s |

| RECOATING SYSTEM |

| Main Structure | Marble recoated frame, marble elevator holder, and marble scanning system base |

| Coating Mode | Intelligent position vacuum recoating |

| Vertical Resolution Ratio | 0.0005mm |

| Repeat Positioning Accuracy | ±0.01mm |

| Layer Thickness | 0.05mm~0.2mm |

| Accuracy | L≤150mm, ±0.1mm;

L>150mm, ±0.1%*L |

| CONTROL SOFTWARE |

| Motion Control System | Closed-loop |

| Machine Control Software | KINGS 3D control software |

| Input Data File Format | STL/SLC |

| Operating System | Windows 10 |

| Network Type and Protocol | Ethernet, TCP/IP |

| INSTALLATION CONDITION |

| Electrical Requirement | 200-240VAC 50/60Hz, single-phase,10A |

| Ambient Temperature | 20-26ºC (72-79℉) |

| Relative Humidity | <40%,non-condensing |

| First Tank Resin | 130kg |

| WARRANTY |

| Machine | Two years |

| Laser | Two years |

If you would like to know more about this machine, please refer to the detailed datasheet below.

Contact us to get a quote about the best SLA 3D printer.

How Does SLA 3D Printer Work?

The SLA machine begins drawing the layers of the support structures, followed by the part itself, with an ultraviolet laser aimed onto the surface of a liquid thermoset resin. After a layer is imaged on the resin surface, the build platform shifts down and a recoating bar moves across the platform to apply the next layer of resin. The process is repeated layer by layer until the build is complete.

Newly built parts are taken out of machine and into a lab where solvents are used to remove any additional resins. When the parts are completely clean, the support structures are manually removed. From there, parts undergo a UV-curing cycle to fully solidify the outer surface of the part. The final step in the SLA process is the application of any custom or customer-specified finishing. Parts built in SLA should be used with minimal UV and humidity exposure so they don’t degrade.

What materials are used for SLA printing?

The following table summarizes the advantages and disadvantages of the most commonly used resins.

| Material | Characteristics |

|---|

| Standard resin | + Smooth surface finish

- Relatively brittle |

| High detail resin | + Higher dimensionally accuracy

- Higher price |

| Clear resin | + Transparent material

- Requires post processing for a very clear finish |

| Castable resin | + Used for creating mold patterns

+ Low ash percentage after burnout |

| Tough or Durable resin | + ABS-like or PP-like mechanical properties

- Low thermal resistance |

| High temperature resin | + Temperature resistance

+ Used for injection molding and thermoforming tooling |

| Dental resin | + Biocompatible+ High abrasion resistant- High cost |

| Flexible resin | + Rubber-like material- Lower dimensional accuracy |

If you want to know more about the best SLA 3D Printer, please contact us.