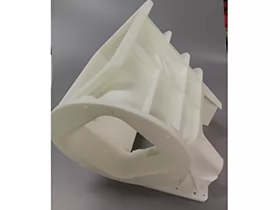

Prototype is an early sample, model for verification before mass production, which is used to evaluate a new design to enhance precision by system analysts and users. Prototype are widely used in industrial manufacturing, whose function lies not only in checking the appearance and structure of the design, but also in lowering cost by avoiding the huge expense loss before mass production.

As a professional Rapid Prototyping 3D Printing supplier, we can custom products according to your requirements. Just contact us.

Advantages

Kings 600Pro Rapid Prototyping 3D Printing brings computer graphic data into any shape of parts within several hours, which greatly shortens product development period, improves

productivity and reduces production costs. Kings 600Pro Rapid Prototyping Machine has been the best seller because of medium printing size, flexible in printing prototype big and small.

Reasons for its standing out among different brands are fast printing speed and long term printing stability

Enhanced Printing Efficiency

Intelligent high speed scanning system, 15m/s

Variable laser spot and variable power

Automatic identifying upskin and downskin with differentiated parameters

Different Parameter database with different layer thickness

Long-term Printing Stability

Key components from international top brand: Optowave laser from US, Scanlab galvanometer from Germany

Full marble structure for enhanced recoating and scanning stability

High stiffness light recoater to ensure recoating accuracy and efficiency

Application field

Kings SLA 3D Printer is not only used to make prototype to check the design before mass production, but also use to replace traditional mould in small batch production, personalized customization, and products with complicated structure. Meanwhile, Kings 600Pro Rapid Prototyping Machine is also used to print prototype for mould to test the function before final production.

What is Rapid Prototyping?

Rapid prototyping is the fast fabrication of a physical part, model or assembly using 3D computer aided design (CAD). The creation of the part, model or assembly is usually completed using additive manufacturing, or more commonly known as 3D printing.

Where the design closely matches the proposed finished product it is said to be a high fidelity prototype, as opposed to a low fidelity prototype, where there is a marked difference between the prototype and the final product.

Rapid Prototyping benefits

Fast and effective communication of design ideas

Effective validation of design fit, form, and function

Greater design flexibility, with the ability to run quickly through multiple design iterations

Fewer production design flaws and better end-products.

If you are interested in our products, please contact us as soon as possible.

How does Rapid Prototyping Work?

Rapid Prototyping, also known as 3D printing, is an additive manufacturing technology. The process begins with taking a virtual design from modeling or computer aided design (CAD)

software. The 3D printing machine reads the data from the CAD drawing and lays down successive layers of liquid, powder, or sheet material — building up the physical model from a

series of cross sections. These layers, which correspond to the virtual cross section from the CAD model, are automatically joined together to create the final shape.

Rapid Prototyping uses a standard data interface, implemented as the STL file format, to translate from the CAD software to the 3D prototyping machine. The STL file approximates the

shape of a part or assembly using triangular facets.

Typically, Rapid Prototyping systems can produce 3D models within a few hours. Yet, this can vary widely, depending on the type of machine being used and the size and number of

models being produced.

Recommended 3D Printing Material: UV Resin KS408, UV Resin KS608, UV Resin 158T