SLA is an early method of 3D printing. The first equipment was patented in 1984 by Charles "Chuck" Hull, and the first commercial machine was developed by 3D Systems in 1988. But how does it work? What applications can it be used for? Find out the answers here, in our complete guide to SLA.

The SLA process uses photopolymerization to produce 3D models using UV-sensitive resin. This is solidified by the passage of a laser layer after layer. It provides one of the most qualitative printing surfaces of existing 3D printing technologies.

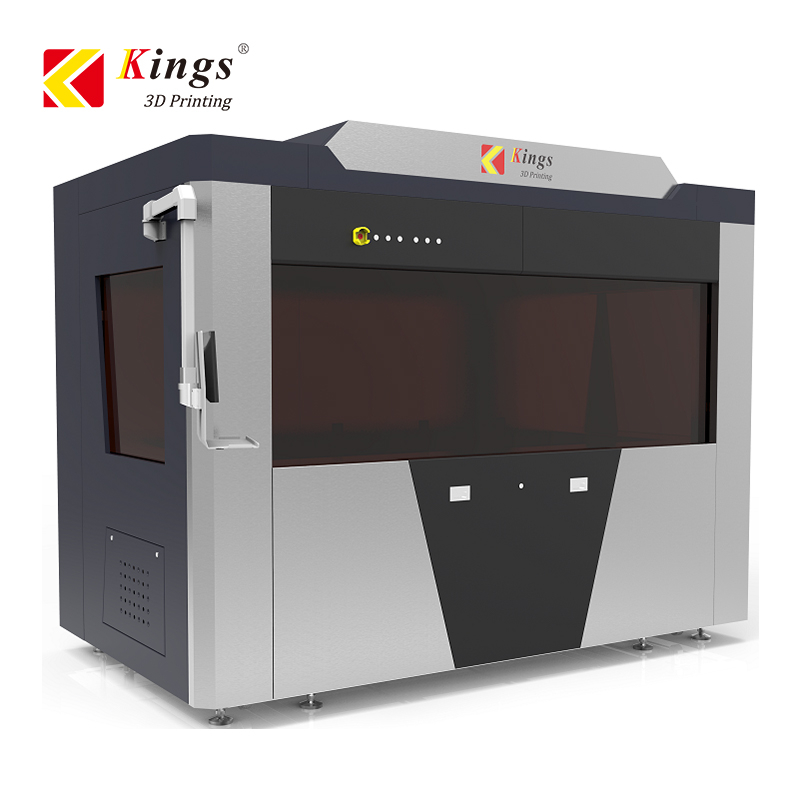

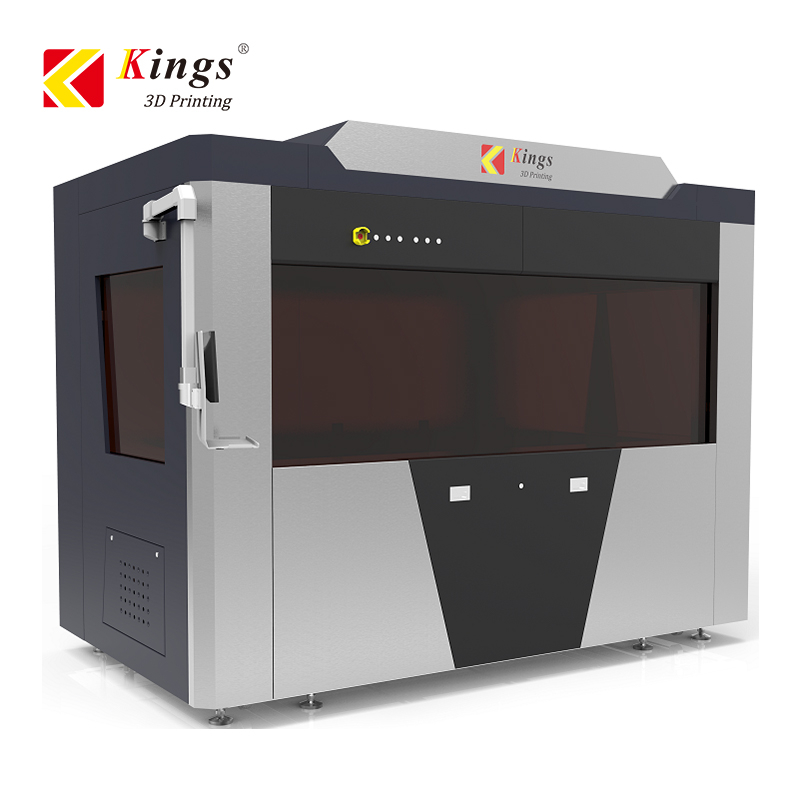

SLA 3D printers use liquid printing material and a UV protection cover (usually white, yellow, or brown). The max printing size of Kings 2700 Pro is 2700*900*800mm.

(Kings SLA 2700 Pro)

How Does SLA Work?

As with any 3D printing technique, a 3D digital file is required. This can be obtained via CAD software (SolidWorks, Sculpt, or SelfCAD for example). These files (usually STL files) are sent to a slicer, which cuts the model into thin layers to print. The instructions are then sent to the 3D printer.

SLA machines contain a resin tray, a mobile platform (Z axis), a scraping system (X-axis), a UV laser, focusing optics, and a mirror galvanometer (X and Y axes). Kings SLA 3D printer uses an Optowave laser from the US and a Scanlab Galvanometer from Germany.

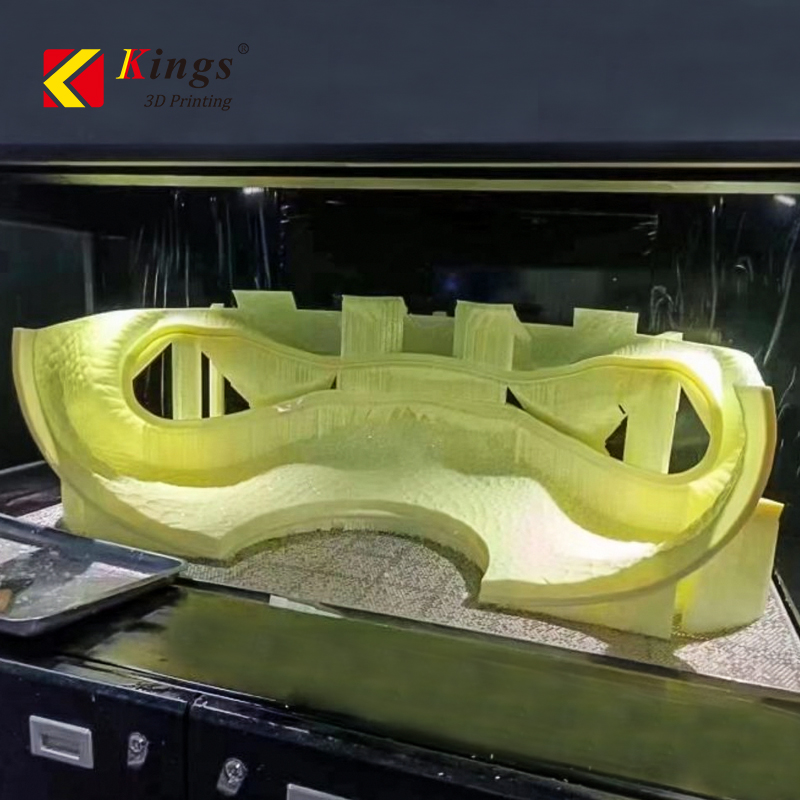

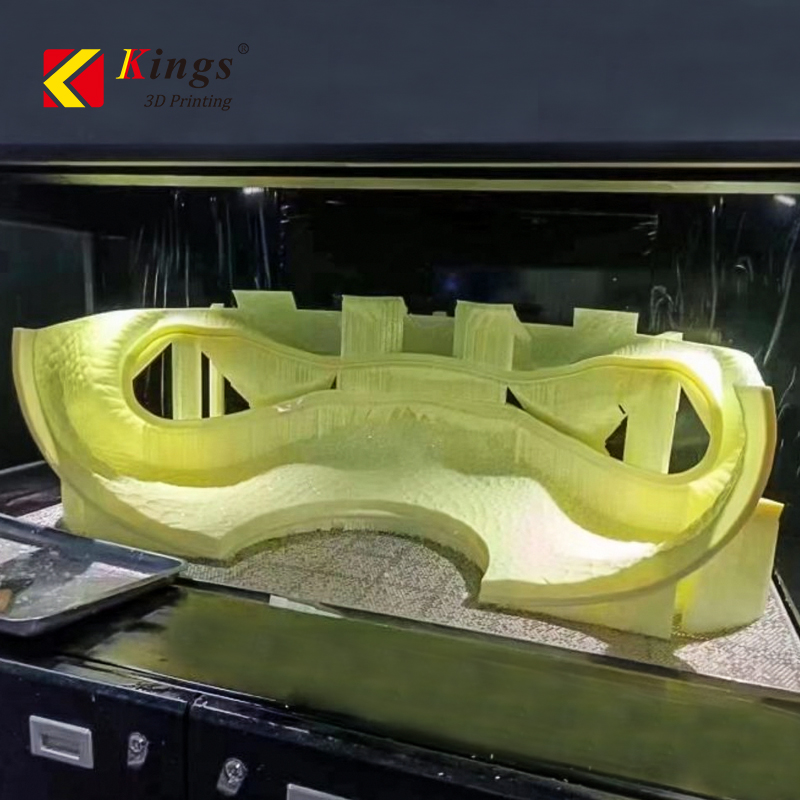

The laser beam sweeps the surface of the liquid resin according to the digital 3D model supplied to the printer. After one layer has been solidified, the platform descends to a level. The next section is then solidified. There are as many printing cycles as there are layers necessary to obtain the complete volume of the piece.

Post-printing Process

Once the printing is finished, a step of cleaning the room, using a solvent (usually isopropyl alcohol also called isopropanol), is necessary in order to remove the excess non-solidified resin. Unlike other techniques such as Selective Laser Sintering and Fused Deposition Modeling, UV post-treatment is usually required to finalize the photo-polymerization process to maximize the strength of the material.

As with fused deposition modeling technology, SLA uses scaffolds when printing complex shapes. In the manner of scaffolding, they provide support for the parts that extend into the vacuum They are removed during post-processing.

If you are interested in Kings SLA 3D Printers, feel free to contact us!

Author: Harry/ Lili Lu/ Christine