The automotive industry stands on the brink of a technological revolution, with 3D printing emerging as a disruptive force poised to redefine the way vehicles are designed, manufactured, and maintained. From rapid prototyping to customized parts production, 3D printing technology offers a myriad of benefits that are reshaping the landscape of automotive manufacturing.

Rapid Prototyping and Design Iteration:

Traditionally, developing prototypes for new vehicle models involved lengthy and costly processes. With 3D printing, automotive manufacturers can rapidly produce physical prototypes directly from digital designs. This accelerated prototyping enables engineers to test and refine designs quickly, reducing time-to-market and fostering innovation. By iterating through multiple design concepts efficiently, automakers can optimize vehicle performance, functionality, and aesthetics with greater precision.

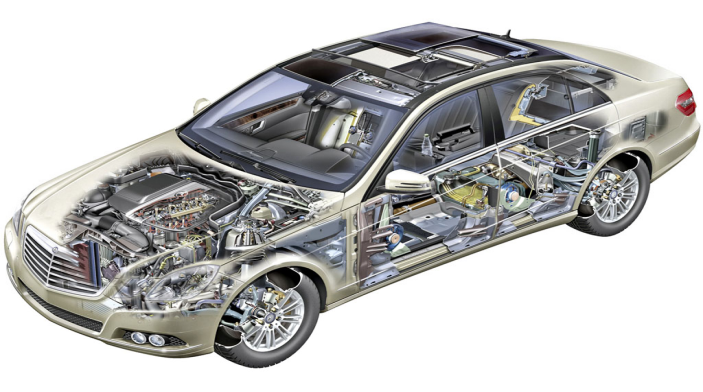

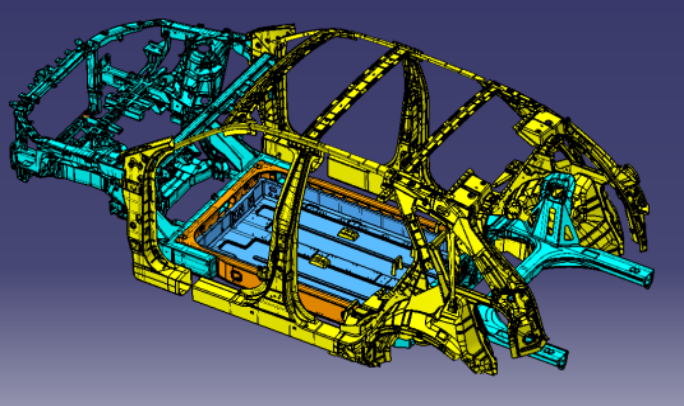

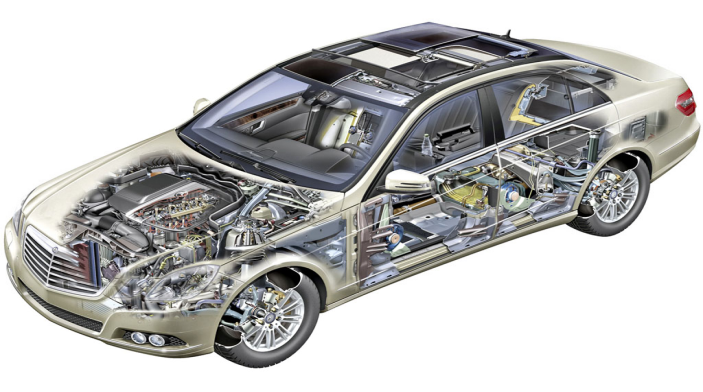

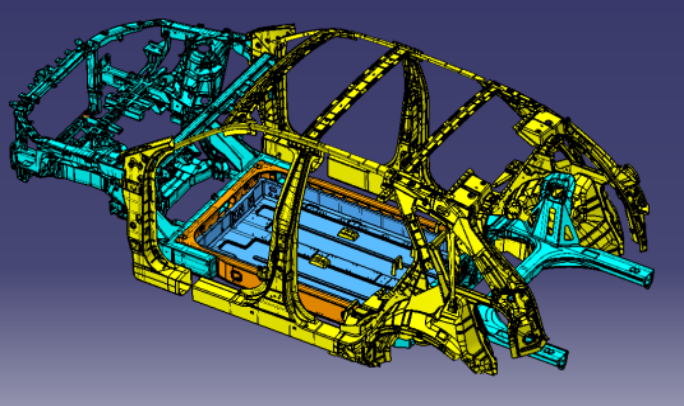

Customized and Lightweight Components:

One of the most significant advantages of 3D printing in the automotive industry is the ability to create highly customized and lightweight components. By leveraging advanced materials such as carbon fiber-reinforced polymers and metal alloys, 3D printing enables the production of complex geometries that are impractical or impossible to manufacture using traditional methods. This customization extends to interior features, exterior body panels, and even engine components, allowing for personalized vehicle configurations tailored to individual preferences and performance requirements.

Supply Chain Optimization:

3D printing has the potential to revolutionize the automotive supply chain by decentralizing production and reducing reliance on centralized manufacturing facilities. Instead of maintaining vast inventories of spare parts, automotive manufacturers can adopt a distributed manufacturing model, producing components on demand closer to the point of use. This streamlined approach minimizes lead times, inventory costs, and transportation emissions, enhancing supply chain resilience and responsiveness to market demands.

Sustainability and Environmental Impact:

In an era increasingly focused on sustainability, 3D printing offers significant environmental benefits to the automotive industry. By optimizing material usage and minimizing waste generation, additive manufacturing reduces the environmental footprint associated with traditional manufacturing processes. Additionally, the ability to recycle and reuse excess powder and scrap material further enhances the sustainability credentials of 3D printing in automotive production. As the industry strives to meet stringent emissions targets and embrace circular economy principles, 3D printing technology emerges as a valuable ally in driving sustainable practices and minimizing ecological impact.

On-Demand Manufacturing and Aftermarket Support:

3D printing technology facilitates on-demand manufacturing of spare parts, addressing inventory challenges and obsolescence issues faced by the automotive aftermarket. By maintaining digital inventories of part designs, manufacturers can produce components as needed, eliminating the need for large-scale production runs and costly tooling. This agile approach enhances aftermarket support, reduces downtime for vehicle repairs, and prolongs the operational lifespan of vehicles, ultimately enhancing customer satisfaction and brand loyalty.

The integration of 3D printing technology into the automotive industry heralds a new era of innovation, agility, and sustainability. From accelerating design iteration to enabling customized components and optimizing supply chains, additive manufacturing offers a multitude of opportunities for automakers to gain a competitive edge in an increasingly dynamic market. As the technology continues to evolve and mature, its transformative impact on the automotive industry is poised to reshape the way vehicles are conceived, manufactured, and maintained, driving progress towards a more efficient, sustainable, and interconnected mobility ecosystem.

Author: Nora/Christine