Keywords: SLM, DED, metal 3D printing, selective laser melting, directed energy deposition, Kings 3D printer, industrial 3D printing, metal additive manufacturing

Metal additive manufacturing is rapidly evolving, with several technologies competing for dominance in industrial applications. Among them, Selective Laser Melting (SLM) and Directed Energy Deposition (DED) are the most widely discussed. While both enable the production of metal components, their technical approaches, application focus, and final part quality differ significantly.

What is SLM?

Selective Laser Melting (SLM) uses a high-powered laser to fully melt metal powder layer by layer inside a powder bed. This process achieves near-net-shape parts with excellent density and precision. SLM is known for producing components with complex geometries, fine details, and mechanical properties comparable to or even exceeding traditional manufacturing.

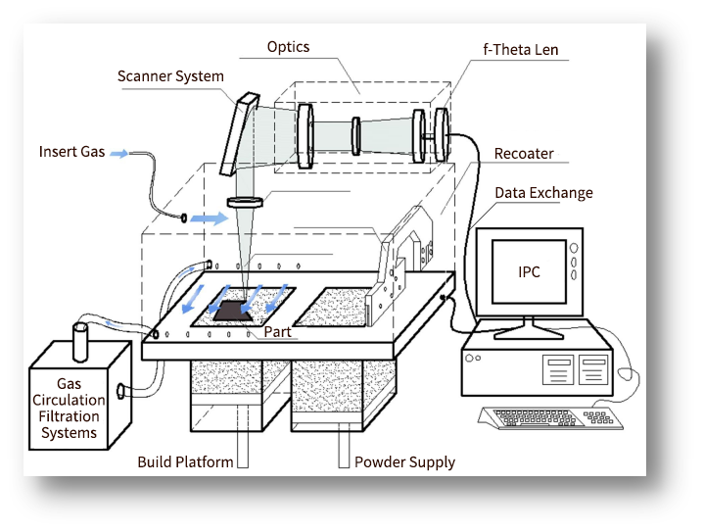

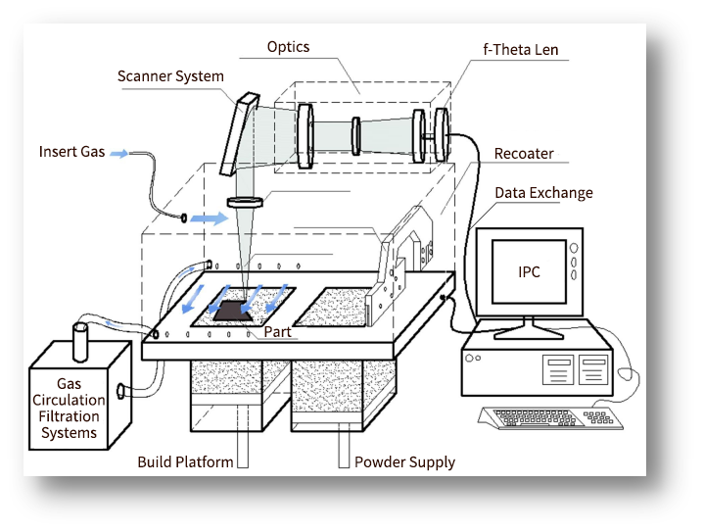

(Printer Structure Diagram of Kings' SLM M50/100/150/280 series)

What is DED?

Directed Energy Deposition (DED) feeds metal powder or wire directly into a melt pool created by a focused energy source (laser, electron beam, or plasma arc). While DED allows for rapid material deposition and is useful for repairing or adding features to existing parts, the resolution, surface quality, and accuracy of finished parts are generally inferior compared to SLM.

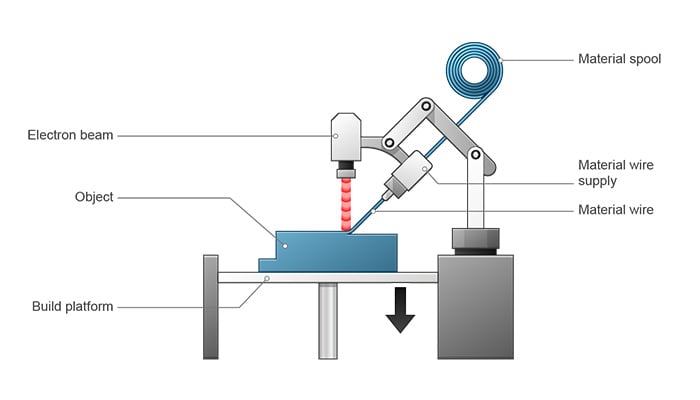

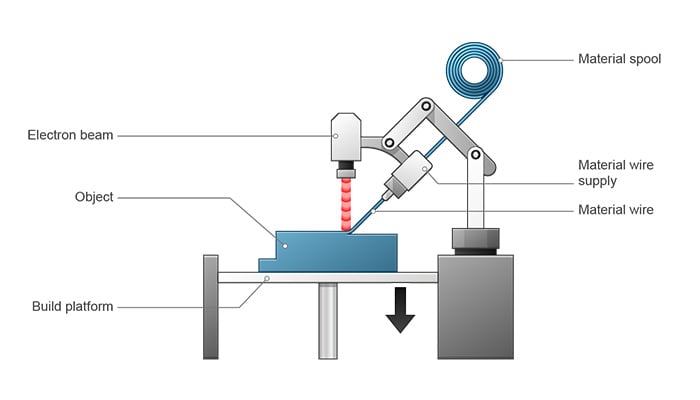

(Printer Structure of a DED 3D Printer, cr: 3DNatives)

Why Choose Kings' SLM Technology?

At Kings, we focus on advancing industrial-grade SLM metal 3D printers to meet the highest demands of aerospace, defense, automotive, and tooling industries. Our printers deliver:

Large-format build volumes for oversized, complex components

Multi-laser systems for high efficiency and accuracy

Reliable closed-loop powder handling and real-time process monitoring

Superior material compatibility, from titanium alloys to high-temperature steels

While DED has its niche in repair applications, the future of high-performance metal additive manufacturing lies in SLM technology. With Kings' expertise and continuous innovation, manufacturers can achieve unmatched precision, quality, and productivity.

Kings' Commitment to SLM Technology

At Kings, we are dedicated to advancing industrial-grade SLM metal 3D printers to meet the highest demands of aerospace, defense, automotive, and tooling industries. Our systems deliver:

Large-format build volumes for oversized, complex components

Multi-laser configurations for high efficiency and precision

Closed-loop powder handling and real-time process monitoring

Broad material compatibility, including titanium alloys and high-temperature steels

DED remains valuable in certain applications, particularly repair. However, for industries prioritizing accuracy, material performance, and design freedom, SLM continues to set the benchmark.

With Kings’ expertise and ongoing innovation, manufacturers gain a reliable path to superior part quality and production efficiency.

(Kings SLM M650 Printer)

Conclusion

Both SLM and DED have important roles in the additive manufacturing landscape. DED offers advantages in repair and large-scale deposition, but for those seeking the highest precision and design flexibility, SLM stands out. Kings' advanced SLM metal 3D printers are empowering global manufacturers to achieve new standards in industrial innovation and productivity.