Keywords: Kings M450F, metal 3D printer, SLM 3D printing, quad-laser 3D printer, additive manufacturing, industrial 3D printing, aerospace 3D printing, defense 3D printing, Formnext Shenzhen

At Formnext Shenzhen, Kings will unveil our latest innovation, the M450F, a medium-format metal 3D printer designed to set new benchmarks in reliability, precision, and productivity. Beyond scaling up build size and efficiency, the M450F represents a complete upgrade in mechanical modules, electrical systems, and software architecture compared to both previous Kings models and mainstream machines on the market.

Mechanical, Electrical, and Software Enhancements

The M450F integrates improvements across every subsystem:

Mechanical: Smooth powder spreading, stable quad-laser coordination, and robust structure for long-duration builds.

Electrical: Redundant monitoring and fault-response mechanisms ensure stable operation under demanding conditions.

Software: Powered by Kings' self-developed AMUDA control platform, with front-end/back-end isolation for uninterrupted printing. Flexible BP options include Kings' own or third-party solutions like Materialise and VoxelDance.

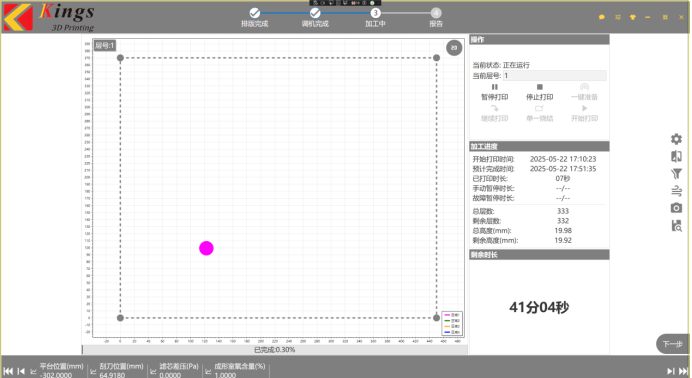

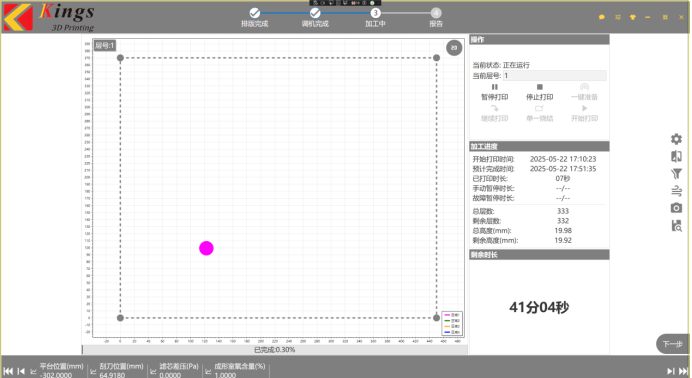

(Kings SLM M450F 3D Printer)

Reliability by Design

Advanced mechanisms for consistent industrial performance:

Closed-loop Z-axis servo control: Accuracy and stability for every build

Torque anomaly protection: Safeguards recoater and powder axes

Environmental self-regulation: Stable build chamber conditions

Real-time powder monitoring: Alerts to minimize downtime

Thermal & Powder Management Innovations

Substrate Preheating (up to 200℃): Reduces thermal stress, improves first-layer bonding

Continuous Powder Supply: Non-stop refilling with real-time level monitoring

Safe Powder Handling & Cleaning: Glovebox station for low-oxygen part removal, isolating operators from hazardous dust

Process Monitoring & Quality Assurance

Comprehensive traceability system includes:

High-definition cameras for layer inspection

Sensors for pressure, temperature, oxygen, and powder condition

Automated logging of operational data, alarms, and environmental changes

This ensures full visibility and traceability throughout the build process, supporting industries where certification and repeatability are critical.

Key Advantages:

Large Build Volume – 450 × 370 × 400 mm capacity for oversized parts

Quad-Laser Bidirectional Printing – High-speed, high-accuracy builds

24/7 Reliability – Designed for uninterrupted industrial production

Material Flexibility – Supports titanium alloys, high-temp alloys, stainless steels, tool steels, and more

The Kings M450F is more than an incremental upgrade — it is a comprehensive rethinking of SLM machine architecture, combining reliability, safety, and efficiency in a single platform. From aerospace to defense, automotive to tooling, the M450F empowers manufacturers to produce complex, high-performance parts with confidence and consistency.

As it makes its debut at Formnext Shenzhen, the M450F stands as a milestone in Kings’ pursuit of industrial-grade additive manufacturing excellence.

For more information, feel free to contact us here!

Author: Christine/Irene