With the rapid progress of "Made in China 2025", the ceramic manufacturing industry has also undergone profound changes and is transforming towards the direction of "intelligence and digitalization". After years of development, 3D printing technology has played an increasingly important role in the production process of ceramics, and ceramic printing technology based on various solutions has made great progress.

The 33rd Guangzhou Ceramics Exhibition KINGS booth

Shenzhen KINGS 3D Printing Technology Co., Ltd, a national high-tech enterprise dedicated to the research, development and innovation of 3D printing, is committed to providing efficient and environmentally friendly 3D printing solutions. It has applications in the fields of hand model, footwear, automotive, aerospace, ceramics, medical dentistry, mechanical equipment, electronics and electrical appliances, construction, etc. It has helped thousands of domestic enterprises to improve their product development and production efficiency by more than ten times, and has been exported to dozens of overseas countries.

KINGS Jiangxi production base

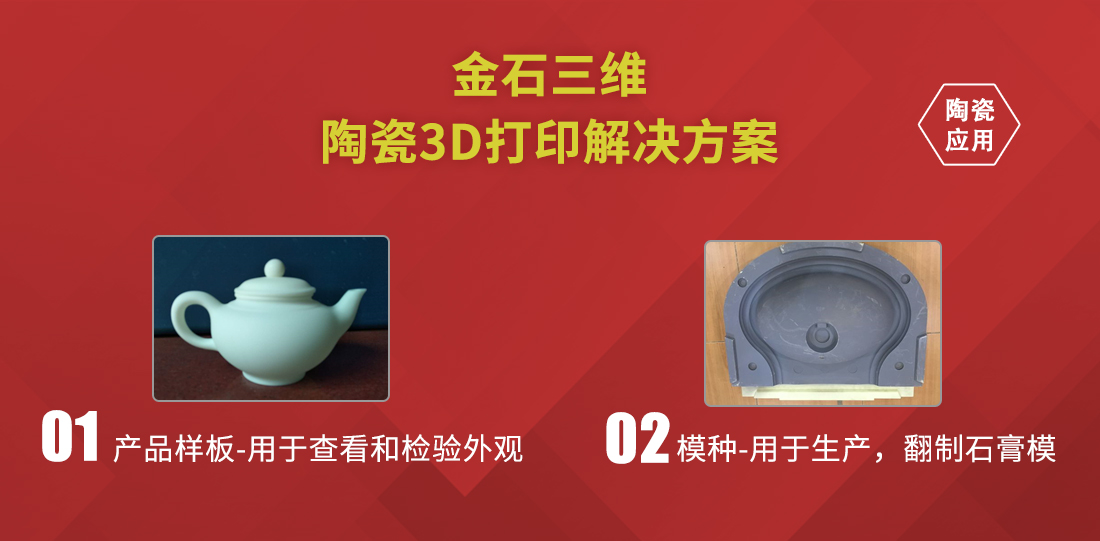

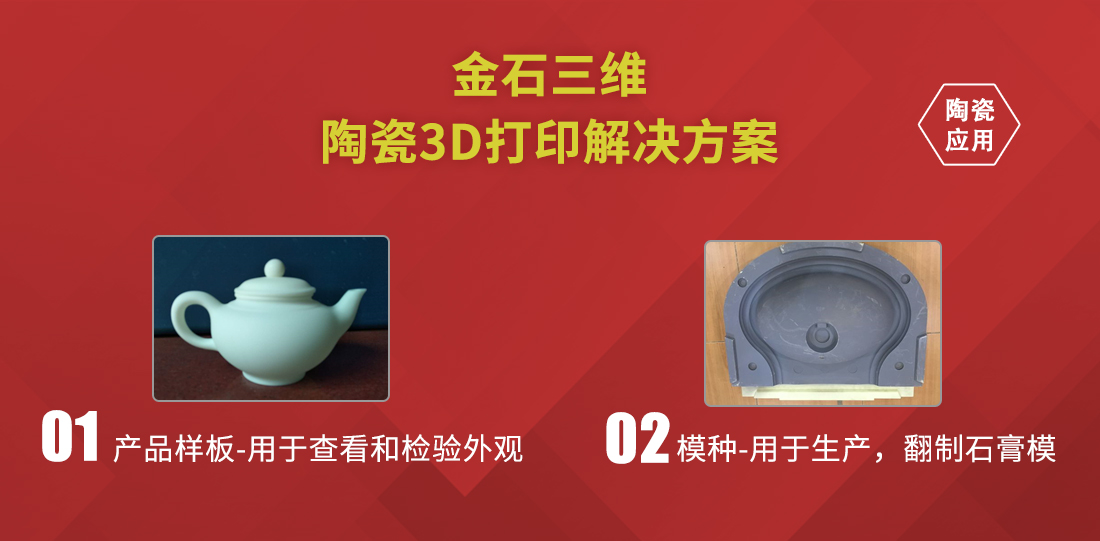

KINGS ceramic 3D printing solutions, is through KINGS 3D printing equipment, SLA3D printing technology is deeply applied in the field of daily ceramics, bathroom ceramics, art ceramics, etc. Through the three-dimensional lithography technology, the liquid photosensitive resin is instantly cured, so as to get any geometric shape of the items, can be integrated to print a variety of large products. It is mainly applied to new product development and appearance verification assembly and inspection assembly in ceramics industry, including product samples, mold master cores, resin mold masters, micro-hole molds, etc.

KINGS ceramic 3D printing solutions

KINGS ceramic 3D printing solution What does it bring to the bathroom industry?

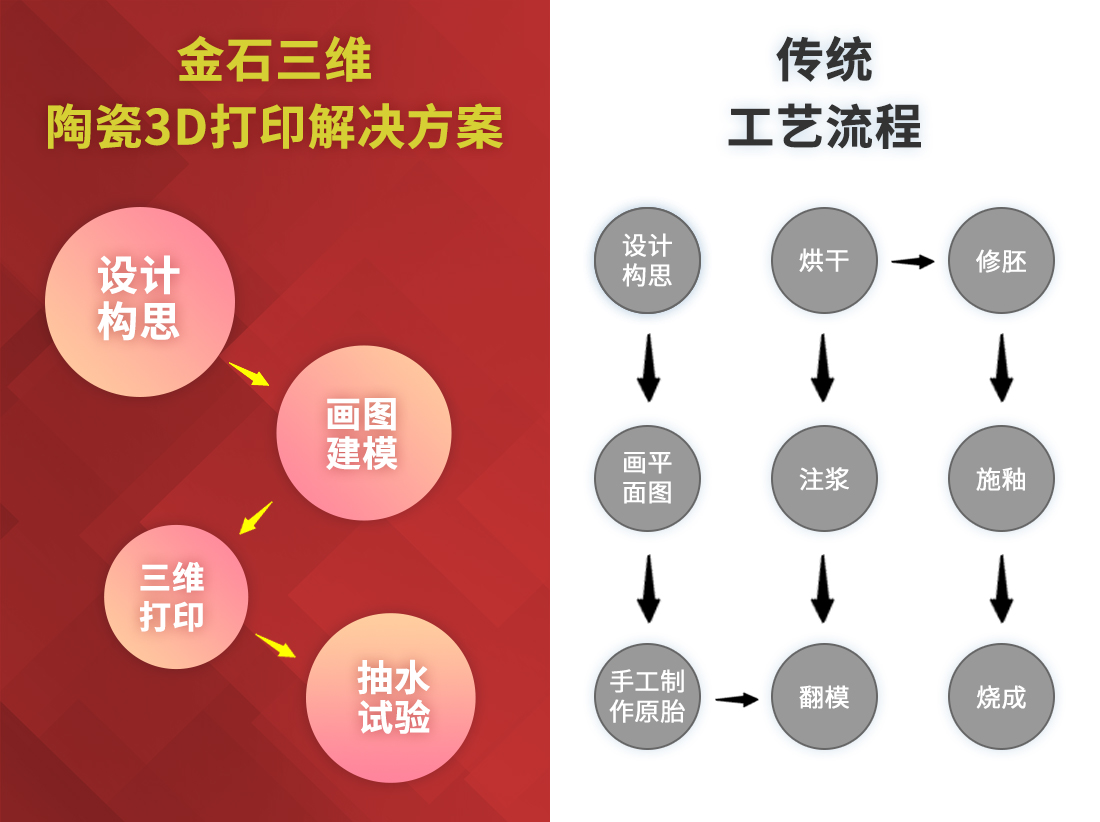

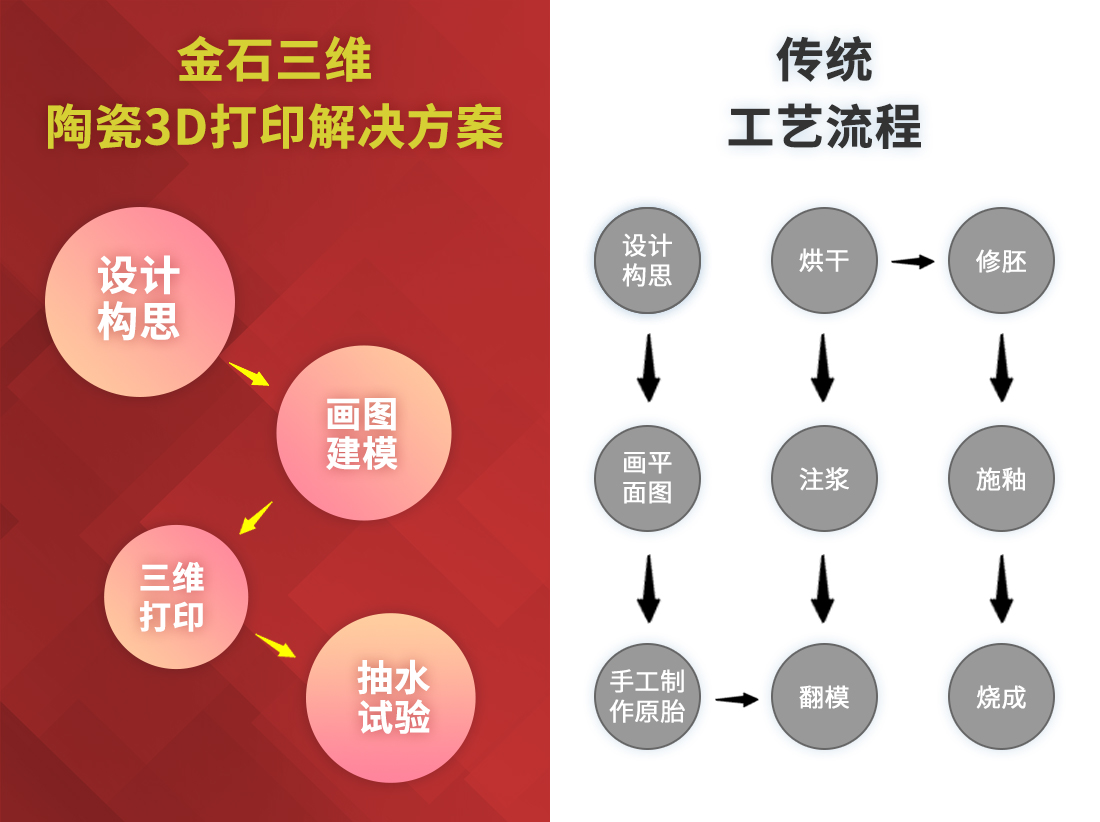

1、Simplify the process, the production cycle of half a year to 3 days

A ceramic sanitary ware product, from the idea to the finished product, using the traditional process after dozens of tedious processes, often takes three months or even longer. With KINGS ceramic 3D printing solutions, all this has completely changed, 1-3 days to print out the new product. Toilets, tanks, flushing pipes, even toilet lids and water parts can be printed in one go and connected to tap water to do flushing experiments.

Prototype toilets made with KINGS Kings SLA 3D printers can be directly tested for pumping to verify that the toilet's pumping function meets industry standards. Of course, we can also install various electronic components on the 3D printed smart toilet prototype to experience other functions of the product.

KINGS 3D printed toilet master mold

2、3D printing ceramic molds, efficient and environmentally friendly

Kings SLA 3D printer, not only can be used to make ceramic product prototypes, but also can be used to make mold masters mold cores, microporous production molds, 3D printing resin molds can be turned into plaster molds, but also to make finished ceramic products. Sanitary ceramics, architectural ceramics, daily ceramics, electric ceramics, industrial ceramics, etc. can be used. Compared with the traditional process, it has the advantages of high efficiency, labor saving, less land occupation and no pollution.

KINGS 3D printed ceramic tea set

A ceramic bathroom product, there is almost no pure straight line! KINGS ceramic 3D printing solutions, can achieve 360 ° no dead angle printing, any structure and shape can be easily produced, while the production of extremely fine pattern, such as the following 3D printing ceramic bowl, can express the details of the surface pattern. 3D printing simplifies the production process of ceramic mold, any product only need to draw and print 2 steps, and It is extremely time consuming to face the complex structure by hand. And manual production is prone to errors that can lead to a complete rework.

3D printed ceramic bowl

3, big data wisdom, a U disk to manage the entire factory

Ceramic industry data precipitation all based on the old craftsman's head and huge inventory, a variety of molds accumulated over the years occupies a huge storage space, and difficult to find. Using Kings industrial grade 3D printer, all the product data can be saved in electronic devices, which can be pulled out anytime when needed to do innovative design on the computer side, which is beneficial to new product development and saves huge management cost.

Super large size SLA 3D printer: JS-1700

3D printing as an emerging technology, the future must enter the intelligent production line. kings ceramic 3D printing solutions, through the 3D printing molding process to create ceramic sanitary sample model, not only to achieve digital intelligent manufacturing of ceramic sanitary products, ceramic sanitary products manufacturing and development cycle from six months to within a week, greatly enhance the product development and manufacturing cycle; at the same time can print out some of the traditional production technology can not be manufactured out of the sample model, so that the product shape is more unique and beautiful, the product details are more delicate and beautiful.