A number of operations are carried out once the metal part is printed out. These steps are termed as SLM Post Processing. The post-processing plays a great role in getting a final good part. Generally, it includes part unloading, de-powdering, heat treatment, part cut-off, machining, surface finishing, and inspection.

Part Unloading& De-powdering

Once metal 3D Printing is done, we need to take the part off the metal plate and that is called part unloading. The unloading is generally manually done on the machine. At the same time, there will be some wasted powder after each printing. We can recycle those metal powders by sieving them with the sieving machine to remove the condensates and bigger semi-melted particles.

Heat Treatment

Heat treatment helps to reduce the internal thermal stresses caused while the parts are being printed. This process is done by the furnace before we separate the parts from the plate. By doing this, the mechanical properties of the parts will be greatly improved and it helps to reduce the warping of the part.

Part Cut Off

The part has to be cut off from the metal plate after the heat treatment is done. There are three ways to cut the supports off the plate. The first one is manual chiseling which means to chisel the supports off the plate by hand. The second one is Bandsaw. It is may results low precision of the parts so sometimes we do not suggest it. The last one is Wire EDM, which is the most common and precise method for part cut-off.

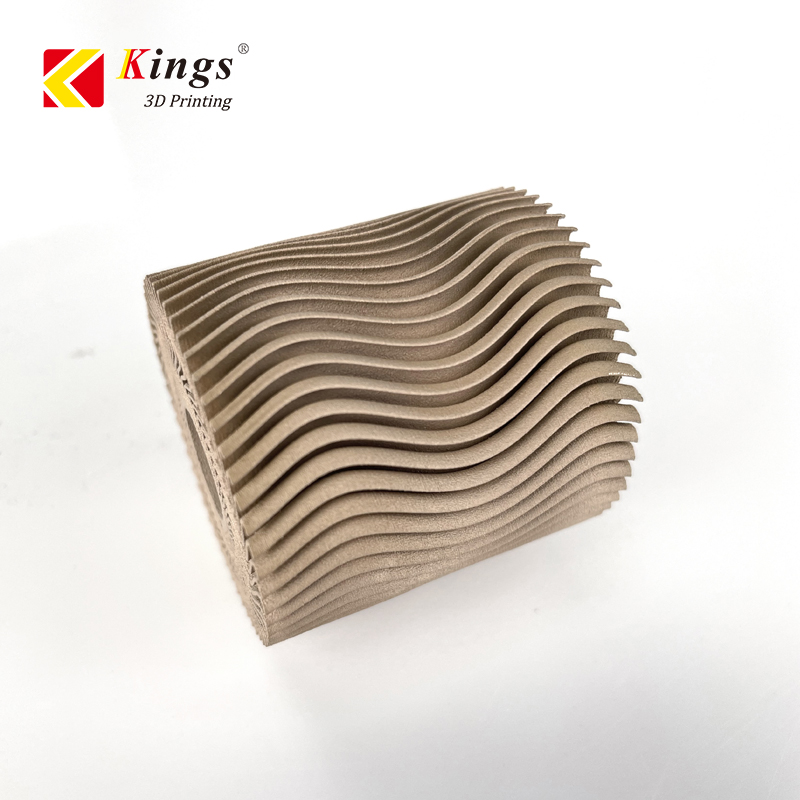

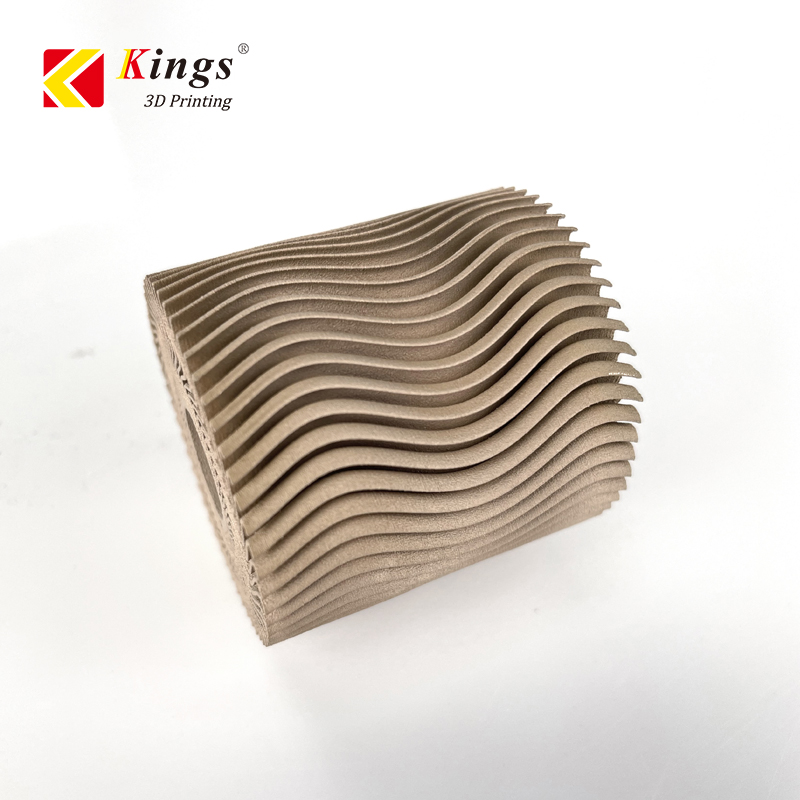

Machining & Surface Finishing

Machining is needed for the SLM printed parts to reach better surface quality. When we do machining, part-specific jigs and fixtures are needed to clamp the part to make sure it does not move randomly.

Inspection

The final step of post-processing is to inspect the size of the projects. Depending on the dimension, the measuring instrument is selected.We generally choose vernier calipers for measurement. Sometimes we also measure other mechanical properties of the part to make sure that the mechanical properties of the printed part meet the requirements of clients.

Kings 3D is always offering clients state-of-the-art SLM equipment and we are also professional in making precise metal parts. The application of SLM printing is widely and promising.

For more details, please visit our website: http://kings3dprinter.com.

Contributor: Lily/Yami