The shift from prototyping to production means 3D printing must become more automated. Prototyping involves iteratively producing successive versions of a part, each one better or different than the last. This is the process of determining the final configuration for a design, which is then handed off to production.

Production is completely different; the design is fixed, but a large number of parts must be produced. Parts must be produced in the most efficient and timely manner, and each part must meet the minimum quality standards for that particular part.

Prototyping is not production

In additive manufacturing, the two methods may actually use the same 3D printing equipment, but they are done in very different ways because of the different goals.

Unfortunately, because of the initial focus on the prototype market, 3D printing developed as a stand-alone technology. Operators would work near the machine, manually operating it as they printed iterations of parts. To date, most 3D printers have been designed using this mode of operation.

While this is still ideal for prototyping, it is definitely not suitable for production. Many 3D printers are not suitable for today's highly automated factories that operate at peak efficiency.

How do you automate 3D printing?

There are multiple ways to solve this dilemma, although few 3D printer manufacturers have taken the radical step of completely redesigning their equipment around production principles. Most have modified their equipment in a variety of ways.

The most common approach is to "plug in" to the manufacturing center's Industry 4.0 backbone. This is a series of digital protocols that connect all systems together and allow for optimization through analytics and real-time control.

Another approach is to try to eliminate much of the manual process required by almost all 3D printers: removing completed prints. This requires physical labor that should be truly eliminated if maximum efficiency and predictability are the goals.

Scientists have developed several systems that actually perform this operation, one of which is 3DQue's VAAPR system, which allows for the automatic removal of prints upon completion. Others have similar systems.

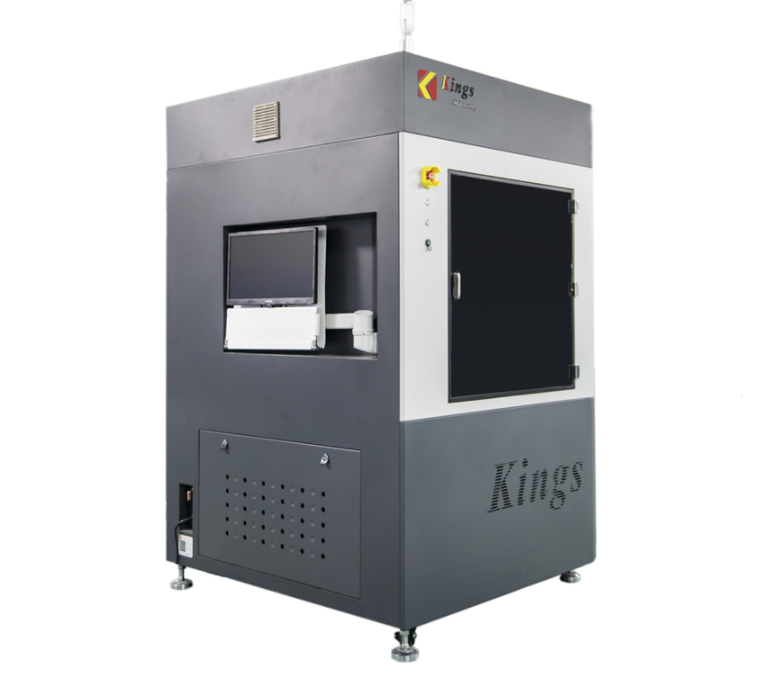

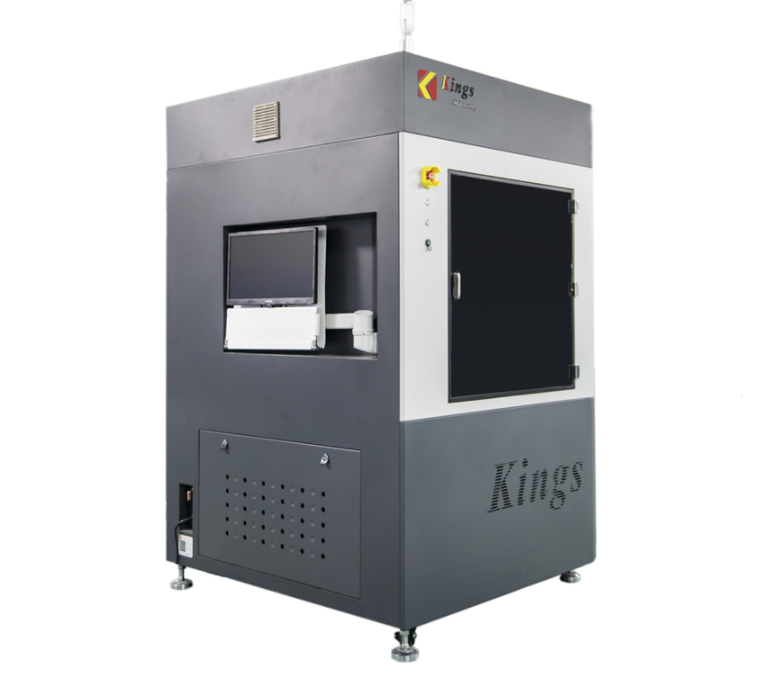

KINGS 600Pro Quick Casting 3D Printer

Robotic Automation

However, while automatic removal of prints is an important labor-saving step, there is still a lot of work to be done.

Almost all parts must undergo various types of post-processing, depending on the printing process used and the desired part quality.

Some 3D printer manufacturers have developed integrated systems to automate "their" part of the process. But for most parts, they are just one of many parts used in a complex manufacturing process that involves other manufacturing processes. Parts may need to be painted, coated, drilled, glued, mounted and countless other possibilities. The problem is how to tie all of these together to automate the entire process.

Ford has started adding KUKA robots to its Advanced Manufacturing Center to replace humans as 3D printer operators, apparently with some success. This robotic system is wheeled, which means it can operate multiple machines and even transport parts to different workstations for further processing.

In the long run, this approach could be the way things go, as it is impossible to build automated 3D printers that can meet all possible manufacturing needs. The concept of a robotic system with human dexterity could solve almost any manufacturing workflow challenge.

The SLA (Stereolithography) 3D printing technology offers a tool-less production of casting models solution, reducing the costs of creating model by 90%, and capable of producing casting models in one-tenth of the time(we call it quick casting). And it has been an ideal method for investment casting. If you have any ideas, please contact KINGS3D today.