Structural integrity in 3D printing is important because 3D prints must not collapse while in operation. This article will provide detailed information on how to make strong 3D printed parts and is helpful for those who have a personal 3D printer or wish to outsource to a rapid prototyping service.

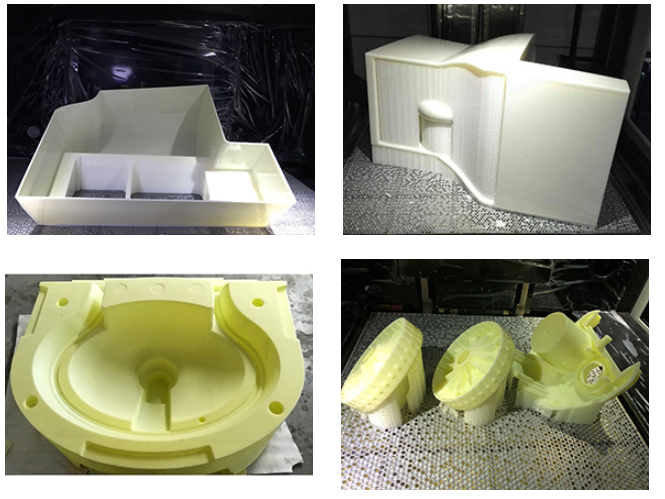

KINGS 800Pro Large Prototype Printer

Adjust printer settings

There are many settings on your 3D printer that you can adjust to get high-quality and powerful prints. Here's how to use them to make powerful 3D prints.

Increasing Wall Thickness

Increasing wall thickness not only enhances the strength of the printed material, but also improves draping and water tightness. For normal products, the wall thickness should be at least ≥ 1.2 mm. You can then increase it to get more strength.

Use thinner layers

Using thinner layers will increase the adhesion and density between subsequent layers, thus enhancing the strength of the 3D printed part. Designers say that going as low as 0.1 mm will maximize strength. However, there is a complementary increase in print time.

Reduce cooling

Cooling is an important process in 3D printing that affects the adhesion of the layer after setup. Since the subsequent layer cannot bond to another layer, rapid cooling will reduce adhesion. However, cooling also depends on the material you are using. PLA, for example, works best with a powerful cooling fan. Therefore, you should reduce the cooling speed depending on the material you are using.

Robust materials

ABS is an excellent 3D printing material for making strong 3D printed parts that are not suitable for mass use. It is a thermoplastic with tough and lightweight properties.

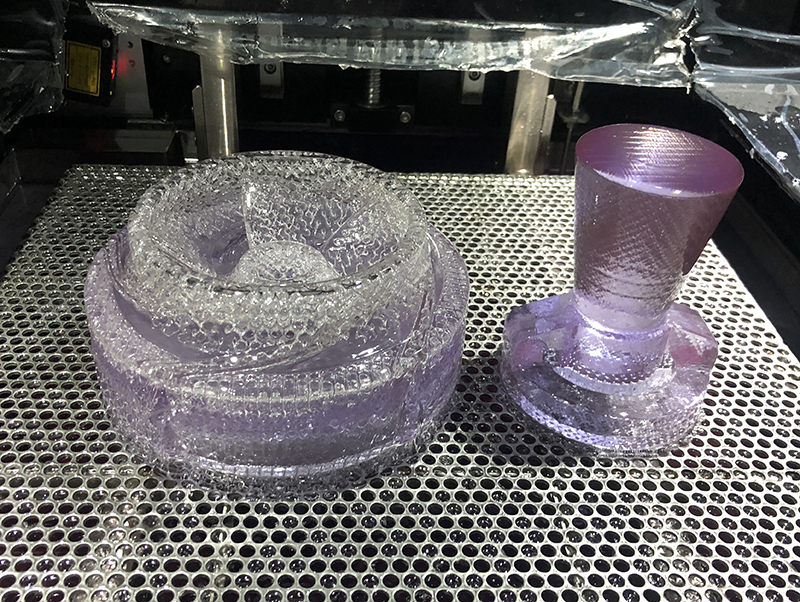

The material used by KINGS3D is mainly UV SLA Resin, a precise and durable ABS-like resin for industrial SLA 3D printers. It is an ideal material for 3D printing with perfect smoothness and detail.

Epoxy Coating

This is not a straightforward method of making strong 3D printed parts, as it occurs after printing. It involves the use of epoxy/polyepoxide to enhance 3D printing. An epoxy coating is an insoluble surface coating made from a hardener and an epoxy coating. It is solvent resistant, durable and tough.

Other Considerations

Annealing is a method of subjecting 3D printed parts to elevated temperatures for the purpose of strengthening. According to tests, annealing is said to increase post-use strength by about 40%.

Electroplating is a popular method because it is practical and reasonably priced. It involves placing a 3D printed part into an electrolyte and plating the metal. When an electric current is passed through the electrolyte, metal ions form a coating around the 3D printed part. This results in a durable 3D print. You can follow KINGS3D to see more of our machines and materials.

Conclusion

Strong 3D printed parts do not collapse when used, which gives you an idea of how to make strong 3D printed parts. It's important. There are three ways to enhance 3D printing: the process itself, the right materials, and post-processing. With any of these methods, you have the opportunity to make strong 3D prints.

Or talk to a prototyping service provider or exchange ideas on how to enhance 3D printed parts. Please contact us if you need to know more.